-

Systems Engineering Services

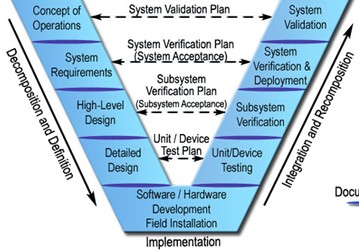

Systems Engineering is an interdisciplinary approach that focuses on defining customer needs and functionality as requirements early in the development cycle, then proceeds with design synthesis and system validation while considering the complete problem. Although organizations subscribe to various industry-specific V-models, such as US DoT (shown), VDI, INCOSE and others, all have the same goal: Provide a quality product that adds business value.

Systems Engineering integrates all the needed disciplines and specialty groups into a structured, team-oriented development process that encompasses concept to commissioning. Systems Engineers consider the needs of all stake holders (business and technical) with the goal of providing a quality product.

These Systems Engineering concepts are ingrained in everything we do at TCB Engineers, whether part of a formal process or an informal methodology. Although many of our engagements deal with the left side and middle of the V-model, it’s our expertise on the right side that enables us to provide complete solutions that literally multiply business value.

TCB Engineers is passionate about Systems Engineering and uniquely positioned to solve our customer’s toughest problems.

Core Competencies

-

Concept of Operations

Concept of Operations (ConOps) is the process of actualizing an idea and removing as many unknown-unknowns as possible. Critical to this process is framing a solution path that is achievable within business, technical and regulatory parameters.

Consider the example of proposing to build a perpetual motion machine; Because it is technically infeasible, the business parameters would need to support an infinite development time.

Key to success is identifying and properly weighting factors that are critical to success early in the process. The ConOps phase is a chance to vet ideas. Where unknown-unknowns cannot be removed, they are captured as risks and monitored closely. Commissioning a proof of concept (PoC) to remove design uncertainty and inform derived requirements is a common approach in product design.

Finally, consider the tangible benefits that the Design for Six Sigma (DFSS) UDMOVC process affords in capturing the Voice-of-the-Customer (VoC), flow down of Critical-to-Quality (CTQ) requirements, and Pugh Concept Selection. Although not ‘silver bullets’, the concepts and intent of these activities can prove invaluable to the process.

TCB Engineers has a reputation of providing novel solutions to the toughest challenges. Our broad industry experience and depth in Systems Engineering result in multi-disciplinary augmented solutions that leverage our customer’s strengths. This activity is often highly constrained by the business plan, which can result in less certainty than desired at phase exit. TCB Engineers leverages experience and strategy to focus on CTQs and drive the process to design certainty.

-

System Requirements

System Requirements is the process of capturing behaviors and requirements at the system, or “black box” level. Key to this process is identifying all applicable established requirements, whether they be regulatory, industry or customer.

For example, the ConOps phase might specify ‘blue paint’ and the System Requirements might decompose this into color coordinates, hardness, and thickness.

The cost of missing or misinterpreting a requirement can be high, as these gaps can undermine system viability. This is especially true for complex systems such as aircraft, where the requirements are so numerous that a requirements management system is needed to organize them hierarchically. For this reason, a requirements management system such as DOORS is routinely utilized to assist with linking and traceability.

TCB Engineers has significant experience with the application and interpretation of regulatory and DoD requirements, requirements decomposition, and requirements management via DOORS. Additionally, we are familiar with formal change management processes used by various organizations, including DCMA.

-

High-Level Design

High-Level Design is the process of performing detailed analysis and trade studies toward defining the fundamental system architecture. To excel in this area, significant experience is required to avoid eventual pitfalls not readily apparent at this early project phase.

Supply chain disruption provides a prime example of this, where knowledge of the industry and a flexible implementation approach inform strategic decisions. Cognizance of these risks and a sensible approach to managing them are key to success.

TCB Engineers has significant design depth and breadth that allows us to infuse projects with the best ideas, solutions and practices from a wide range of engagements. Close ties with our suppliers helps us stay abreast of current events and avoid surprises.

See our RF Engineering service offering

See our Electrical Engineering service offering

See our Test Engineering service offering

-

Detailed Design

Detailed Design is a highly specialized area where dedicated professionals develop specific solutions to the high-level design. Numerous Engineering Design Automation (EDA) and Computer-Aided Design (CAD) tools are in use and leveraging both their strengths and interoperability is key to success.

TCB Engineers provides subject matter expertise (SME) in the areas of RF and Electrical Engineering. In the Electrical Engineering (EE) domain, we excel at analog design and mixed-signal systems where ancillary constraints dictate a creative, multi-disciplinary approach. Our RF Engineering expertise applies in two practical areas: RF Circuits & Systems informs purely RF designs such as RF Welding and software defined radio (SDR), and Signal Integrity informs EMI/EMC and transmission lines. Underpinning this expertise is a solid foundation in Physics, the ‘universal scientific language’.

See our RF Engineering service offering

See our Electrical Engineering service offering

See our Test Engineering service offering

-

Design Verification

Unit/Device Testing

Design Verification is the process of vetting a design solution against the requirements to which it was designed. This encompasses two areas: functional requirements, in which features and operational procedures are verified, and environmental, where the functional envelope is verified across parameters such as temperature, humidity, vibration and altitude.

While functional requirements are relatively straight-forward to verify due to the reuse of design tools, environmental verification requires specialized equipment and techniques that can be daunting. TCB Engineers can help make strategic decisions regarding methodology and make/buy/lease that can significantly affect the viability and utility of the Design Verification process.

It is rarely sufficient to simply rely upon the traceability of the measurement device. Identifying, controlling and quantifying sources of error and their relative contribution to Measurement Certainty is key. Every system we have designed has exhibited unique measurement certainty challenges and solving them creatively and elegantly is a unique characteristic of TCB Engineers.

TCB Engineers has developed hardware and software Design Verification solutions for or a wide range of industries, including medical, avionics, and consumer products, to name a few. In the past, we’ve developed solutions for everything from wind tunnels to high vacuum systems, jet fighters to submersibles, and food production to municipal water processing. This broad experience base enables us to develop novel and efficient solutions to intractable problems.

See our Test Engineering service offering

-

Verification & Validation

Verification & Validation dominates the right side of the V-model, which depicts how realized systems are validated against requirements and ultimately commissioned. Activities are largely determined by the nature of the system; Small, contained systems such as a consumer product may only require Device Testing and System Validation, while a large complex system like an aircraft Line Replaceable Unit (LRU) requires multiple levels of validation.

TCB Engineers provides subject matter expertise (SME) in the area of Verification and Validation (V&V) by leveraging depth of experience in the design, development and commissioning of Automated Test Systems (ATE), Specialized Test Systems (STE), and HALT/HASS systems. Our designs have played a key role in emerging technologies such as MIL-AERO, wind turbines, medical/surgical devices, consumer products, Quantum technology, heavy machinery, semiconductor fabrication, and photonic systems.

See our Test Engineering service offering

-

-

Engineers First

Have a difficult challenge? Experience matters.

All work at TCB Engineers is performed under a Licensed Professional Engineer and we hold close the principles embodied in the NSPE Engineers' Creed.

Our Engineers are naturally curious and our ability to solve the tough problems is part of what defines us. With expertise in Signal Processing, Applied Physics & Mathematics, RF & Wireless, and Information Systems, we’re prepared to take on novel challenges and deliver exceptional results.

See our RF Engineering service offering

See our Electrical Engineering service offering

See our Test Engineering service offering

-

Let's Collaborate

Contemplating a new development or struggling with an existing one?

Caught in a cycle of wholesale outsourcing?TCB Engineers has extensive experience collaborating with customer teams large & small, which allows organizations to augment skillsets instead of wholesale outsourcing.

Taking advantage of our Engineering Services can help ensure project success by anticipating risks and forming collaborative strategies that avoid cost and schedule overruns.

Whether it be invention to entrepreneurship, theory to proof, or ConOps to Phase IV, TCB Engineers is uniquely positioned to be a strategic partner in your next project.

Work Product Samples

Most of our work is not in the public domain, but here's a couple examples we can share.

RF Welder

Balancing size, weight, power, and cost (SWaP-C) isn't easy. See how we helped our customer refresh their product design and maintain their leadership position.

RADAR SAFETY CONTROLLER

We specialize in high reliability designs for harsh environments. See how we engaged in a formal design process to ensure success.

PCBA Test System

Automated test need not be complicated & expensive. See how we helped our customer bootstrap their way into advanced manufacturing.

IoT-Enabled CRDS Sensor for UAV

An academic institution needed a sophisticated UAV payload for research. See how we developed a SWaP-optimized high reliability design with IP-67 rating.